In this article, we are going to tell you about how to apply expanded microspheres in cool roof coating and insulation paint and what’s the advantages. Hopefully, it will help you know more about the expanded microspheres.

Subject of Cool Roof Coating

- Introduction of Expanded Microspheres

- Benefits with Expanded Microspheres

- Properties of Paints with Microspheres

- Suitable Expanded Microspheres Grades

- Preparation of Paints with Microspheres

- Application of Paints with Microspheres

- Basic Formulations and Guidelines to Modify

Introduction of Expanded Microspheres in Cool Roof Coating

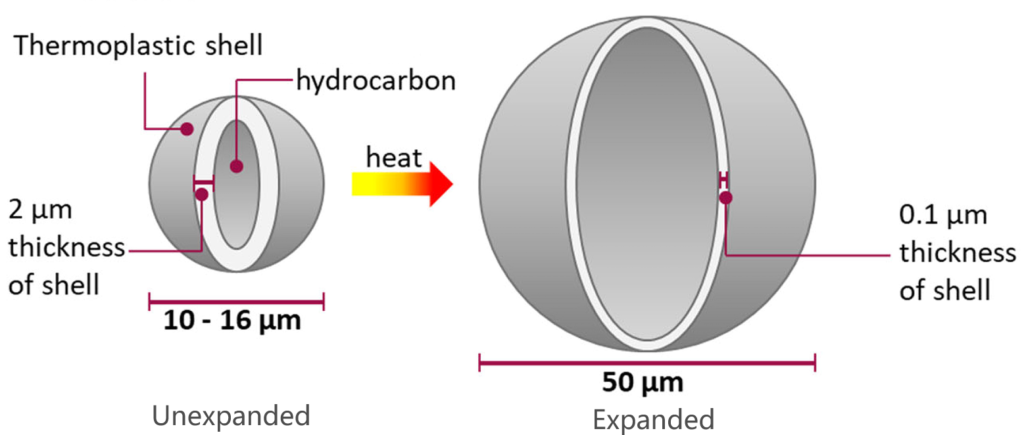

Expanded Microspheres is a super lightweight filler, which will add volume dramatically with small dosage in weight, without losing much of the original properties of your products. Our lightweight fillers allow you to substitute heavier substances with small portions of microspheres and achieve better overall results, saving raw material costs in the process.

- Extremely low density, 20kg/m3;

- Free-flowing white powder, hollow spheres;

- Thermoplastic polymer shell and hydrocarbon gas inside;

Benefits of Cool Roof Coating with Expanded Microspheres

Here are some benefits that can be achieved with microspheres:

- Density Reduction

- Thermal Insulation

- Good Filling Capacity

- Cost Reduction

- Higher Water Vapor Permeability

- Lower Water Absorption

- Matting Surface

- Low VOC Emission

- …

Thermal Insulation

Expanded microspheres are hollow closed cells and encapsulated a large amount of gas. Microspheres create tiny air-filled voids within the paint, improving its thermal insulation property.

Good Filling Capacity

The addition of microspheres increases the solid content per unit volume of the paint, resulting higher filling capacity of the paint and providing better coverage for cracks.

Weight Reduction

Due to the extremely low density of microspheres, the weight of the paints can be significantly reduced. By adding 5-10 percent by weight of wet expanded microspheres, a can of 20 kg of paint will reduce its weight to 10-15 kg.

Cost Reduction

The weight reduction of paints saves workload, energy and transportation costs. Moreover, the low demand of microspheres for binders means saving the binder cost.

Higher Water Vapor Permeability

Paints with microspheres have higher permeability compared to the ordinary paints, which may extend the shell life of the paint.

Lower Water Absorption

Paints with microspheres have lower water absorption compared to the ordinary paints.

Matting Surface

Adding a small amount of microspheres to the paint can achieve different matting surface with different particle size of microspheres.

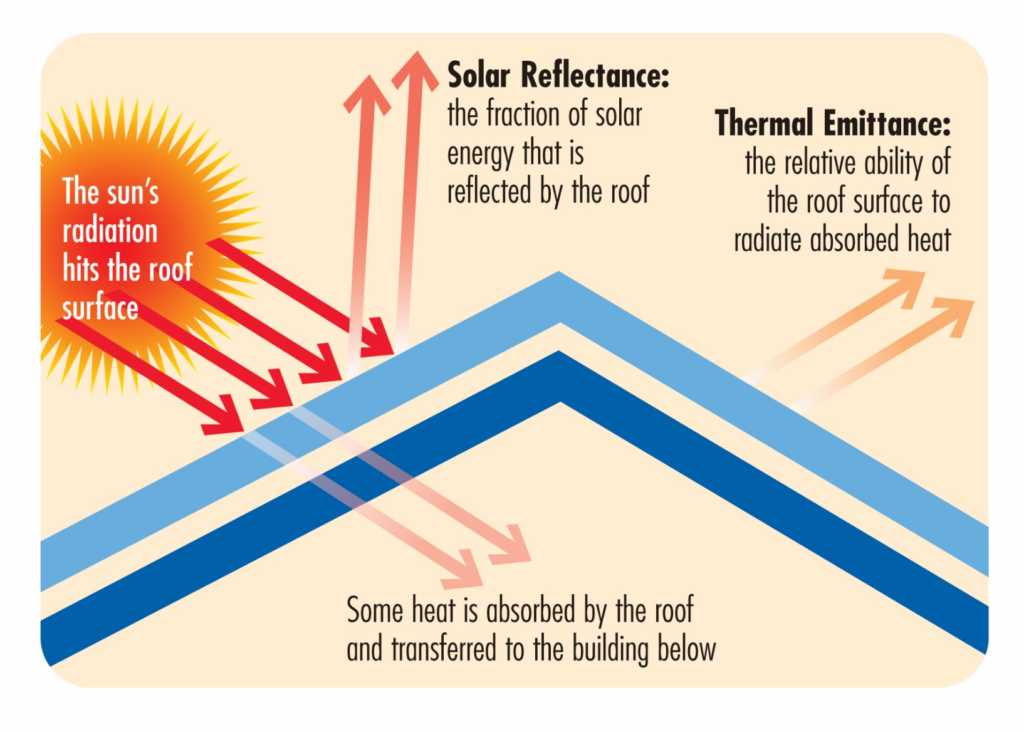

Reflectivity Properties of Cool Roof Coating with Microspheres

The main effect of expanded microspheres is probably reflection rather than insulation. It is not enough to measure only insulating effects .

“Closed packed units of gas filled spheres of diameter ~10-50 micron, makes up a very efficient NIR reflecting system.”

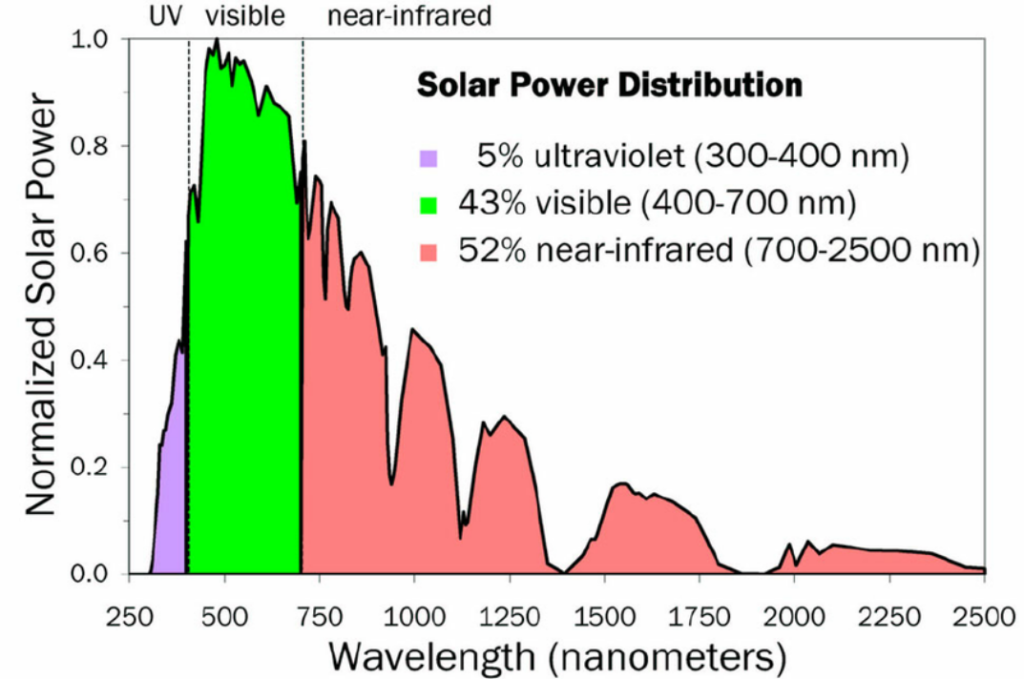

Solar Powder Distribution

As you can see from the chart, most of the solar energy is from near-infrared and VIS. If you the coating could reflective them, the room temperature will certainly decrease.

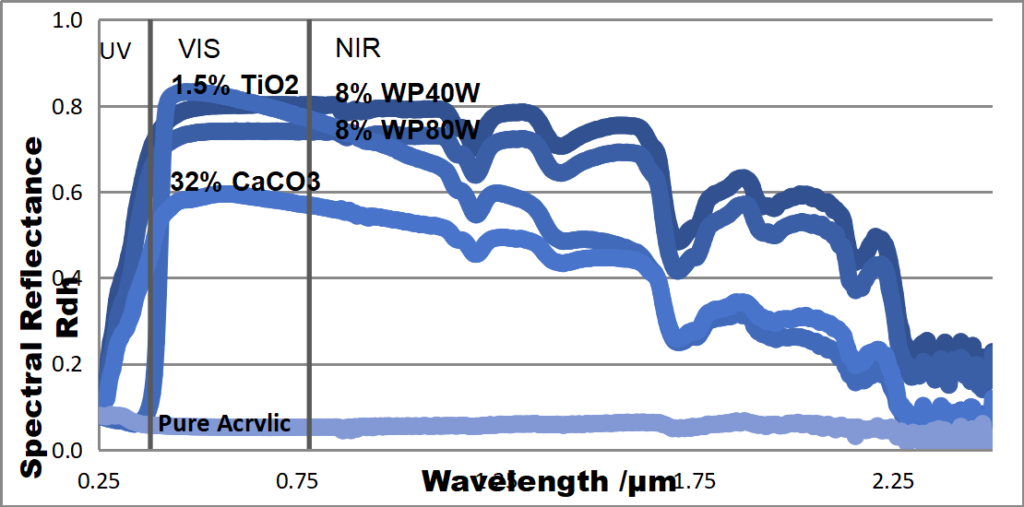

Directional-hemispherical reflectance

As you can see from the chart, TiO2 has better relfection of the VIS than expanded microspheres. Expanded microspheres have better reflection of the NIR than the TiO2.

Suitable Expandable Microspheres Grades

You can choose the suitable microspheres according to your needs.The following is several microspheres that can be used as additive to waterborne paints.

| Grade | Average Particle Size (μm) | Solid Content (%) | Density kg/m3,Dry |

| WP20W | 20-30 | 15±2 | 30-40 |

| WP40W | 30-50 | 15±2 | 20-30 |

| WP80W | 70-90 | 15±2 | 15-25 |

Preparation of Cool Roof Coating with Microspheres

The preparation can be carried out through the following steps:

- Choose appropriate mixing equipment such as dissolvers, disc mixers, or planetary mixers to disperse and mix the materials.

- Disperse heavy fillers such as pigments and inorganic fillers in the equipment for a period of time.

- Expanded microspheres should be added after step 2, and the stirring speed should be high enough to ensure that the microspheres are fully dispersed.

- Add thickeners to adjust the viscosity.

- Stir all materials evenly.

Application of Cool Roof Coating with Microspheres

- Paints with expanded microspheres can be used by rollers, brushes or even spray guns.

- Due to the low density, microspheres may float after a long-time of storage. Therefore, before using, the paints should be mixed evenly to avoid uneven application.

- It can be applied on surfaces such as concrete, wood, and metal plates.

- Microspheres can be used in interior flat paint, exterior house paint, texture paint, cool roof paint, etc.

Guidelines to Modify Formulations

Below is a basic formulation.

| Ingredients | Material | Parts by weight |

| Expanded Microspheres | WP40W | 5.0~10.0 |

| Water | – | 10.0~30.0 |

| Emulsion | Acrylic | 20.0~45.0 |

| Dispersing agents | – | 0.3~1.0 |

| Pigment | TiO2 | 5.0~20.0 |

| Fillers | CaCO3 | 10.0~20.0 |

| Thickener | – | 0.2~0.5 |

| Defoamer | – | 0.2~1.0 |

A small amount of the following additives can be added as needed:

- Preservative

- Opacifying Extender

- Wetting Agent

- Leveling Agent

- Antifreeze

- PH-adjuster

- Etc

For more applications, please check our application sections:

https://www.expandablemicrosphere.com/applications

For more intesting videos, pleast check our Youtube Channel: